Difference of Forward Integration and Backward Integration – Detail Explanation

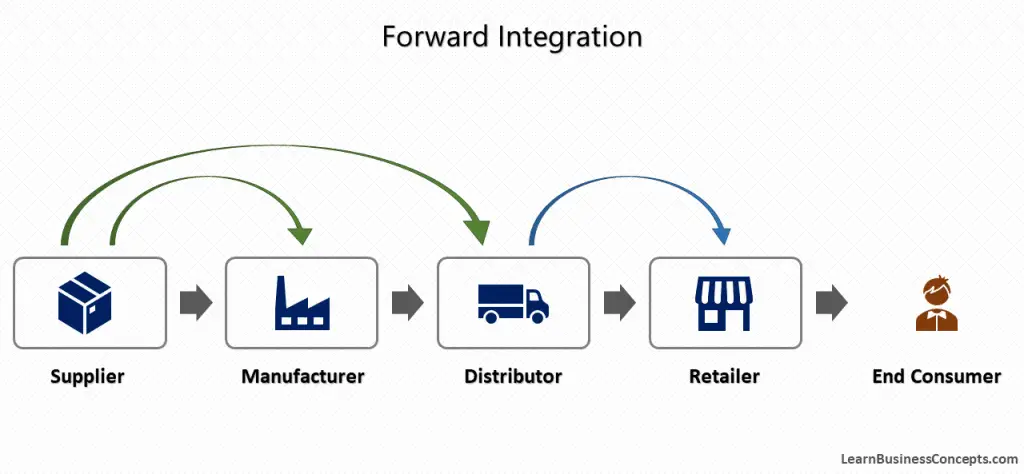

What is Forward Integration?

Forward integration is a strategy where the company gains control of the business activities that are ahead in the value chain. This means the company moves closer to the end consumer, managing how its products are marketed, sold, and serviced. This is a type of vertical integration of the supply chain. Forward integration practically means “removing the middleman”. Manufacturers may skip the wholesalers/retailers in the value chain to sell directly to customers.

For example, Apple manufactures devices like iPhones and MacBooks and sells them directly to consumers through its own Apple Stores and online platform. This allows Apple to control the entire customer experience, ensuring high-quality service and maintaining brand consistency.

Similarly, Tesla manufactures electric cars and sells them directly through its own showrooms and website. By doing this, Tesla bypasses traditional car dealerships, allowing it to directly interact with customers, manage the sales process, and provide after-sales support.

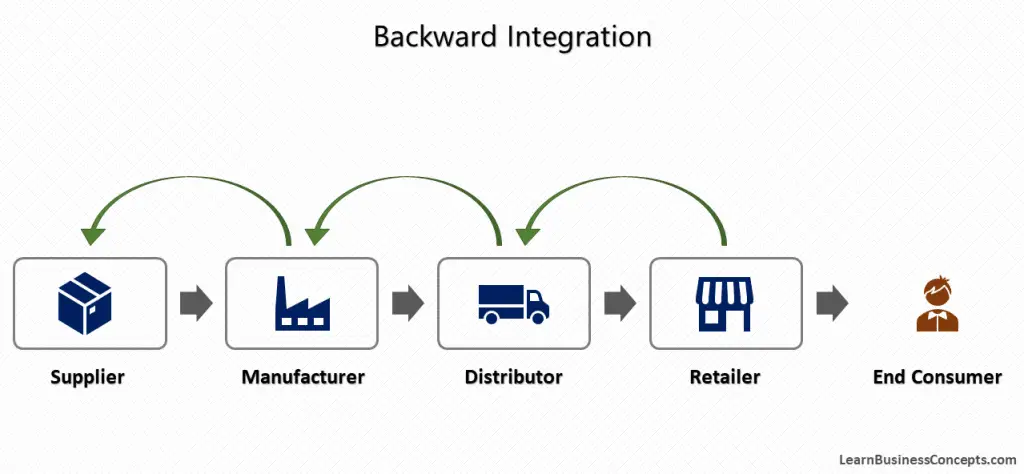

What is Backward Integration?

Backward integration is a strategy where the company gains control of the business activities that were behind in its value chain. This means the company starts producing its own raw materials or components, rather than relying on external suppliers. The company gains control over the raw materials using the backward integration method.

Backward integration is where a company expands across multiple supply chain segments, which are behind its value chain, to control a part or entire production process. This is a form of vertical integration, where the company performs tasks that were formerly performed by its suppliers.

For example, IKEA, the furniture retailer, has acquired forests and wood production facilities. By doing this, IKEA ensures a stable and cost-effective supply of wood for its products. This move allows IKEA to control the quality of its materials and reduce costs, which can lead to lower prices for customers.

Another example is Netflix. Originally a content distributor, Netflix began producing its own movies and TV shows under the Netflix Originals label. This backward integration reduces its reliance on third-party studios, ensures a steady stream of unique content, and gives Netflix full control over its production schedules and quality.

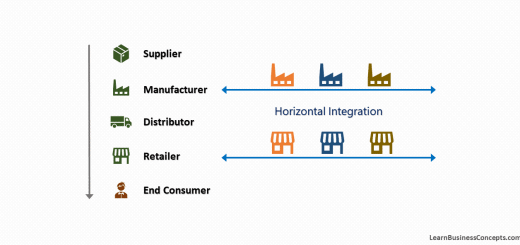

What is Vertical Integration?

Vertical integration is a business strategy where a company expands its operations across different stages of the supply chain within its industry. This can include integrating both upstream (backward integration) and downstream (forward integration) activities.

For example, a company involved in manufacturing might vertically integrate backward by acquiring or controlling its suppliers of raw materials. This allows the company to secure a stable supply of materials, reduce costs, and have more control over the quality of inputs used in production.

On the other hand, vertical integration can also involve forward integration, where a company expands into activities closer to the end consumer. For instance, a manufacturer might start selling its products directly to consumers through company-owned retail stores or online platforms. This helps the company to better control its distribution channels, enhance customer relationships, and capture more value from its products.

An iconic example of vertical integration is seen in the case of Tesla. Tesla vertically integrates by manufacturing its electric vehicles, producing its own batteries and other components, and selling these cars directly to consumers through its own showrooms. By controlling the entire production process and distribution chain, Tesla ensures high-quality standards, accelerates innovation, and maintains a distinct market position in the electric vehicle industry.

Differences between Forward Integration and Backward Integration

Summary of the differences between Forward Integration and Backward Integration explained in the below table,

| Forward Integration | Backward Integration |

|---|---|

| The company gains control of the business activities that are ahead in the value chain | The company gains control of the business activities that were behind in their value chain |

| The company acquire or merge with a distributor | The company acquire/merge with a supplier or manufacturer |

| Gain control over the distribution chain | Gain control over the supply chain |

| The main purpose is to obtain a greater market share | The main purpose is to realize economies of scale |

| Example: FMCG goods production company acquires or starts a distribution company. Now the company can have control over its distribution process. | Example: Clothing manufacturing company acquires or starts a fabric company. Now the company can have adequate raw materials for producing cloths. |

Differences between Forward Integration and Backward Integration are explained in the below points,

1. Definition and Focus

- Forward Integration: This strategy involves expanding a company’s operations closer to the end customer by moving downstream in the supply chain. It focuses on activities such as distribution, retail, and customer service.

- Backward Integration: This strategy involves expanding a company’s operations towards the sources of raw materials or production inputs by moving upstream in the supply chain. It focuses on securing resources, raw materials, and production capabilities.

2. Objectives

- Forward Integration: The main objectives are to enhance control over the distribution and sales process, improve customer experience, and increase market reach. Companies aim to directly engage with customers, control the brand presentation, and capture higher profit margins by eliminating intermediaries.

- Backward Integration: The main objectives are to ensure a stable and cost-effective supply of key inputs, improve quality control, and reduce dependency on suppliers. Companies aim to lower production costs, secure critical materials, and innovate more effectively.

3. Control and Customer Engagement

- Forward Integration: Provides direct control over how products are marketed, sold, and serviced. This direct interaction with customers helps in gathering valuable market insights, fostering brand loyalty, and ensuring consistent customer service.

- Backward Integration: Provides control over the sourcing and production of raw materials or components. This helps in maintaining consistent quality, reducing supply chain disruptions, and optimizing production processes.

4. Market Position and Competitive Advantage

- Forward Integration: Enhances competitive advantage by differentiating through superior customer experience, unique distribution channels, and direct customer relationships. It helps companies capture a larger share of the market and build stronger brand loyalty.

- Backward Integration: Enhances competitive advantage by ensuring reliable access to critical inputs, lowering production costs, and improving product quality. It allows companies to innovate and differentiate their products based on superior materials and components.

5. Operational Focus

- Forward Integration: Emphasizes market expansion, customer engagement, and sales optimization. Companies focus on developing retail networks, enhancing online presence, and improving customer support services.

- Backward Integration: Emphasizes production efficiency, cost control, and quality assurance. Companies focus on acquiring raw materials, improving manufacturing processes, and ensuring consistent input supply.

6. Risk and Investment

- Forward Integration: Involves risks related to retail operations, such as fluctuating demand, higher operational costs, and the complexities of managing customer-facing activities. The initial investment can be substantial, but the potential for higher margins and stronger customer relationships can justify the costs.

- Backward Integration: Involves risks related to the production and procurement of raw materials, such as fluctuating input costs, technological changes, and the complexities of managing upstream activities. The initial investment is often high, but the potential for cost savings and supply chain stability can offset the risks.

7. Supply Chain Impact

- Forward Integration: Affects the downstream part of the supply chain, aiming to improve efficiency and effectiveness in distribution, sales, and customer service.

- Backward Integration: Affects the upstream part of the supply chain, aiming to secure raw materials, enhance production processes, and ensure the availability of essential inputs.

8. Examples

- Forward Integration: Examples include Apple opening its own retail stores, Netflix creating its own streaming service, and Amazon developing its logistics and delivery network.

- Backward Integration: Examples include Ford owning rubber plantations, IKEA acquiring forests for wood production, and Starbucks buying coffee farms.

Why Companies Decided to Move with Forward Integration or Backward Integration?

Companies decide to move with either forward or backward integration based on several strategic considerations and business objectives, which given below,

1. Control Over Supply Chain

Integration allows companies to exert greater control over critical aspects of their supply chain. Forward integration helps in controlling distribution channels, retail operations, and customer interactions, while backward integration ensures a stable supply of raw materials or key components.

2. Cost Efficiency

Companies can potentially reduce costs associated with intermediaries by integrating vertically. Forward integration may eliminate distributor margins, while backward integration can cut out supplier markups, leading to overall cost savings.

3. Quality Control

Integration enables companies to maintain consistent product quality by overseeing production processes and raw material inputs. This control can enhance product reliability, customer satisfaction, and brand reputation.

4. Risk Management

Integrating backward can mitigate risks associated with supply chain disruptions or fluctuations in raw material prices. Forward integration reduces reliance on external distributors, thereby reducing risks related to delivery delays or quality issues.

5. Competitive Advantage

Integration strategies can create competitive advantages by differentiating products or services. Forward integration allows for direct customer engagement and customized service offerings, while backward integration can lead to proprietary technologies or unique sourcing advantages.

6. Innovation and Flexibility

Vertical integration can foster innovation by allowing companies to develop new products, processes, or technologies internally. It also provides flexibility in responding to market changes or customer preferences more swiftly.

7. Market Expansion

Integration strategies can support market expansion efforts by ensuring scalability of operations and adapting to local market conditions. This can be crucial for companies looking to enter new geographic regions or penetrate different customer segments.

8. Long-Term Sustainability

Companies can build sustainable competitive advantages that endure over time by integrating vertically. This includes building resilient supply chains, enhancing operational efficiency, and adapting proactively to industry trends.

What is the Best out of Forward Integration and Backward Integration?

Determining whether forward integration or backward integration is the best strategy depends on the unique circumstances and strategic goals of each company. Both approaches offer distinct advantages and considerations that can significantly impact business operations and competitive positioning.

Forward integration involves expanding a company’s reach towards the end consumer by gaining control over distribution, retail, or customer service activities. This strategy enhances control over how products are sold and serviced, allowing companies to tailor their customer experience, ensure brand consistency, and potentially capture higher profit margins by eliminating intermediaries. Direct engagement with customers also enables companies to differentiate their offerings in the market through personalized services and targeted marketing strategies.

However, forward integration requires substantial initial investments in establishing retail networks or online platforms, and managing customer-facing operations can introduce complexities such as logistics, inventory management, and customer service challenges. Moreover, market dynamics and shifts in consumer behavior can pose risks to the effectiveness of forward integration strategies.

Conversely, backward integration involves expanding operations upstream in the supply chain by acquiring or controlling suppliers of raw materials or production inputs. By producing their own raw materials or components, companies can achieve greater cost control, reduce dependency on external suppliers, and ensure consistent quality across their products. This strategy provides stability in the supply chain, mitigates risks associated with supply disruptions or price fluctuations, and enhances operational efficiency through streamlined production processes.

However, backward integration requires significant capital investments in acquiring production capabilities or developing new technologies, along with ongoing operational expenses and challenges in managing upstream operations. Companies must also consider the potential limitations of over-reliance on internal production capabilities, which could restrict flexibility in responding to changing market conditions or technological advancements.

Ultimately, the choice between forward and backward integration depends on strategic alignment with long-term business goals, market dynamics, resource availability, and risk tolerance. Companies should carefully evaluate the advantages, considerations, and potential impacts of each integration strategy to determine which approach best supports their growth objectives and enhances their competitive edge in the marketplace. By aligning integration strategies with their unique business circumstances, companies can effectively navigate challenges, capitalize on opportunities, and achieve sustainable growth and profitability.

Challenges of Forward Integration and Backward Integration

Challenges of Forward Integration

- High Initial Investment

Establishing retail stores, distribution channels, or direct-to-consumer platforms requires significant upfront capital investment. This can strain financial resources, especially for smaller companies or those entering new markets. - Operational Complexity

Managing customer-facing operations involves complexities such as logistics, inventory management, and customer service. Ensuring consistent service quality across multiple locations or online platforms requires robust operational strategies and skilled workforce management. - Market Dynamics

Consumer preferences and buying behaviors can change rapidly, impacting the effectiveness of forward integration strategies. Companies must continually adapt their retail strategies and product offerings to meet evolving customer demands and competitive pressures. - Risk of Over-Expansion

Rapid expansion of retail operations can lead to over-extension, where companies struggle to maintain profitability or operational efficiency across all locations. Balancing growth with sustainability and profitability is crucial to avoid over-exposure in competitive markets. - Dependency on Consumer Trends

Success in forward integration heavily relies on accurately predicting and responding to consumer trends. Failure to anticipate shifts in market preferences or technological advancements can result in obsolete inventory and lost opportunities.

Challenges of Backward Integration

- Capital Intensity

Acquiring or developing production capabilities requires substantial financial investment in infrastructure, technology, and skilled labor. The upfront costs associated with building or acquiring production facilities can strain financial resources and impact liquidity. - Operational Complexity

Managing upstream operations involves technical expertise in production processes, regulatory compliance, and coordination with suppliers. Companies must ensure seamless integration of new capabilities while maintaining operational efficiency and meeting quality standards. - Supply Chain Risks

While backward integration mitigates risks related to supplier dependencies, companies assume responsibility for sourcing raw materials or components. This includes managing logistics, maintaining inventory levels, and navigating global supply chain complexities. - Technological Advancements

Rapid advancements in technology and production methods require continuous investment in research and development. Companies must innovate to stay competitive and leverage technological advancements to enhance production efficiency and product quality. - Market Demand Variability

Fluctuations in market demand and seasonal variations can impact production planning and inventory management. Companies must adopt agile manufacturing strategies to respond quickly to changing market conditions and customer preferences.

FAQs of Forward Integration and Backward Integration

1. What is integration in business?

Integration in business refers to strategies where companies expand their operations either towards the end consumer (forward integration) or towards the sources of raw materials (backward integration) within their supply chain.

2. Why do companies pursue integration strategies?

Companies pursue integration to gain more control over their supply chain, reduce costs, improve product quality, enhance customer experience, and strengthen their competitive position in the market.

3. What is forward integration?

Forward integration involves a company expanding its operations towards the end consumer by taking control of distribution, retail, or customer service activities.

4. What is backward integration?

Backward integration involves a company expanding its operations upstream in the supply chain by acquiring or controlling its suppliers of raw materials or production inputs.

5. What are examples of integration strategies?

Examples include Apple selling its products through Apple Stores (forward integration), IKEA owning forests for its wood supply (backward integration), and Tesla producing its own batteries for its electric vehicles (vertical integration).

6. What are the benefits of integration strategies?

Benefits include cost savings by eliminating intermediaries, improved quality control, reduced supply chain risks, enhanced market competitiveness, and potential for innovation and differentiation.

7. What are the challenges of integration strategies?

Challenges may include high initial investment costs, complexities in managing integrated operations, risks associated with market changes or technological advancements, and potential disruptions to existing supplier relationships.

8. How do integration strategies impact a company’s operations?

Integration strategies impact operations by reshaping how products are produced, distributed, and sold. They can streamline processes, improve efficiency, and provide greater flexibility in responding to market demands.

9. What factors should companies consider before implementing integration strategies?

Companies should consider factors such as market demand, financial feasibility, scalability of operations, regulatory considerations, and potential impacts on existing business relationships.

10. What are the long-term implications of integration strategies?

Long-term implications include enhanced resilience to market fluctuations, sustainable cost advantages, improved customer satisfaction, and the ability to adapt more quickly to changes in the competitive landscape.

Recommended Articles:

- Vertical Integration